What kinds of finned tubes are used in air cooled heat exchanger?

The tubes can be of virtually any material available, such as carbon steel, stainless steel, Admiralty brass, or more exotic alloys. The minimum preferred outside diameter is one inch. Some manufacturers sometimes use smaller tubes, but most of the process coolers have tubes which are 1.0", 1.25", or 1.5" OD. The minimum tube wall thicknesses vary with the material. In some cases the design pressure and design temperature of the exchanger govern the minimum thickness.

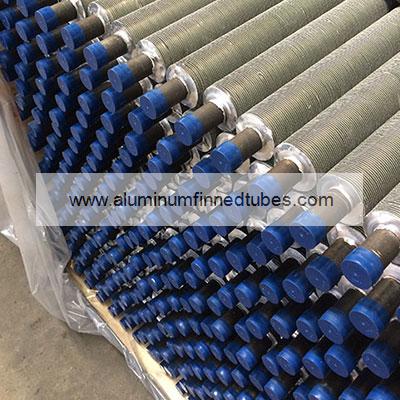

The fins are almost always of aluminum material. The most common type of fin is the helically wrapped, L-footed type. These are used where the process temperatures are below about 350 deg. F. The API specification calls for cast zinc bands at the ends of the tubes to prevent the fins from unwrapping. Some of the better manufacturers also use cast zinc bands at the tube supports. For higher process temperatures, most customers prefer either embedded or extruded fins. The embedded fins have the highest temperature capabilities. They are made by a process which cuts a helical groove in the OD of the tube, wraps the fin into the groove, then rolls the upset metal from the tube back against the fin to lock it into place. The tube wall must be thicker with embedded fins because of the groove.

In some applications customers often prefer extruded fins. Extruded fins are made by putting an aluminum sleeve (sometimes called a muff) over the tube, then passing the tube through a machine which has rollers which squish the aluminum out to form fins. The process is similar to a thread-rolling machine. The end result is a fin which has extremely good contact with the tube, and no crevices to allow corrosion to start on the tube OD. Extruded fins are often used in coastal locations or on offshore platforms for this reason.

Contact:Abby

Phone: +86 18252727002

Email:finnedtube@163.com

Add:No.1 Zhicheng Road, Chazhen Industrial Zone, Maji Town

We chat